- Trang chủ

- Giới thiệu

- Dự án

- Giải pháp

- Sản phẩm

- Ứng dụng

- Tin tức

- Liên hệ

![]() Tầm nhìn

Tầm nhìn

Định hướng trở thành công ty tích hợp hệ thống điều khiển hàng đầu Việt Nam

![]() Sứ mệnh

Sứ mệnh

Mang đến cho khách hàng hệ thống điều khiển hiện đại và tối ưu hóa sản xuất

![]() Triết lý kinh doanh

Triết lý kinh doanh

Sản phẩm tốt nhất - Giải pháp tốt nhất

HỆ THỐNG ĐIỀU KHIỂN PHÂN TÁN DELTA-V

TÍCH HỢP

TÍCH HỢP TRONG ĐIỀU KHIỂN TĂNG TÍNH AN TOÀN TRONG SẢN XUẤT KINH DOANH

CUNG CẤP NHỮNG GÌ KHÁCH HÀNG CẦN

TIẾT KIỆM

TRONG TẤT CẢ CÁC GIẢI PHÁP CỦA CHÚNG TÔI

CUNG CẤP SẢN PHẨM, HỆ THỐNG ĐIỀU KHIỂN CHO CÁC DỰ ÁN

TIẾN ĐỘ

KỊP THỜI, KỊP LÚC LÀ TIÊU CHÍ PHẤN ĐẤU TOÀN THỂ NHÂN VIÊN

CUNG CẤP THIẾT BỊ ĐO LƯỜNG VÀ ĐIỀU KHIỂN, HỆ THỐNG ĐIỀU KHIỂN

CHẤT LƯỢNG

LÀ NIỀM TIN CỦA TẤT CẢ ĐỐI TÁC

Giới thiệu

Thành lập từ năm 2007. Công ty TNHH TM DV Kỹ Thuật Bảo Nghi là đơn vị chuyên cung cấp thiết bị đo lường, thiết bị điện công nghiệp, thiết bị điều khiển, khí cụ và tự động hóa cho các ngành công nghiệp. Chuyên ngành Dầu khí, Hàng hải, Điện, Công nghiệp Cao su, Công nghiệp Dệt may, Công nghiệp Thực phẩm & Đồ uống,…

Với đội ngũ kỹ thuật dày dạng kinh nghiệm công ty Bảo Nghi đã thực hiều nhiều dự án về hệ thống tích hợp an toàn điều khiển (ICSS) (PCS, FSC, ESD, FGS), điều khiển phân tán (DCS) cho các giàn khai thác dầu khí ngoài khơi Việt Nam, điều khiển và thu thập dữ liệu từ xa (SCADA) cho các nhà máy chế biến công nghiệp, hệ thống điều khiển đồng tốc, hệ thống điều khiển theo lực căng và các hệ thống điều khiển trung tâm khác như: Hệ thống lạnh trung tâm HVAC, hệ thống ADON, hệ thống dán bố xe, hệ thống kiểm tra chất lượng vỏ xe bằng phương pháp nội soi....

Với phương châm mạng lại sự hài lòng nhất cho khách hàng, chúng tôi luôn luôn cố gắn hết sức mình nhằm cung cấp cho khách hàng các sản phẩm với chất lượng cao nhất có thể cũng như chính sách phục vụ khách hàng tốt nhất có thể từ tập thể công ty Bảo Nghi

" Sản phẩm tốt nhất - Dịch vụ tốt nhất " - Đó là kim chỉ nam để chúng tôi hướng đến.

ABOUT OUR COMPANY

WORKING SINCE 1995

We offer transformation solutions for enterprises worldwide that are designed to improve oil & gas production efficiency.

ABOUT OUR COMPANY

WORKING SINCE 2000

To improve the development phase of oil & gas production, our company uses top-notch engineering solutions.

ABOUT OUR COMPANY

WORKING SINCE 2005

Blue Energy offers reliable oil & gas supply solutions to clients worldwide to ensure the fastest petroleum shipping.

ABOUT OUR COMPANY

WORKING SINCE 2005

Blue Energy offers reliable oil & gas supply solutions to clients worldwide to ensure the fastest petroleum shipping.

ABOUT OUR COMPANY

WORKING SINCE 2005

Blue Energy offers reliable oil & gas supply solutions to clients worldwide to ensure the fastest petroleum shipping.

Dự án

Công ty Bảo Nghi rất vinh dự là nhà thầu cung cấp thiết bị và trực tiếp thi công của dự án Nâng cấp hệ thống giám sát và điều khiển cân bằng giàn FPU DH01, Block 05-1a, ngoài khơi Việt Nam.

Giàn đầu giếng Đại Hùng 2 được thiết kế, chế tạo và lắp đặt tại phía nam mỏ Đại Hùng theo quyết định số 732/QĐ-TTCP vào ngày 3 tháng 6 năm 2009 với 8 đầu giếng. Nhằm đưa vào khai thác các giếng 09, 10, 12 Công ty Bảo Nghi tự hào là nhà thầu thiết kế và thi công trực tiếp

Mỏ Sư Tử Trắng pha 1 được đi vào hoạt động vào thàng 9 năm 2012. Trong giai đoạn đầu, dự án được thiết kế bao gồm một Wellhead Platform (WHC-C) riêng biệt, không có người làm việc trên giàn này và được điều khiển bởi giàn xử lý trung tâm Sư Tử Vàng CPP. Tiếp theo là dự án mở rộng pha 1 bao gồm 1 khu vận hành và nhà ở (LQ) và

Giải pháp

'Dòng chảy tương lai' chỉ là bước khởi đầu - đáp ứng sự đổi mới mới của chúng tôi

Graco Lubrication Equiment - Giải pháp bôi trơn tự động cho các máy móc, thiết bị và hệ thống cơ khí truyền động.

Praesent tempor dolor ut tellus ultrices vehicula. Nam tempus lobortis sem sit amet dignissim. Pellentesque blandit ante massa, sit amet egestas augue dapibus ut. Morbi feugiat eleifend sapien, quis laoreet nisl imperdiet vitae. Aliquam erat volutpat. Donec vestibulum vulputate diam.

Thiết bị phân tích

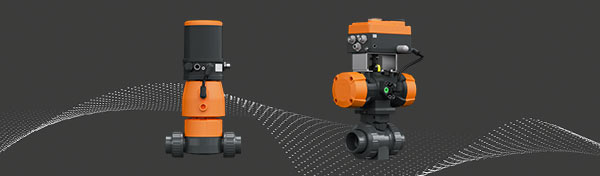

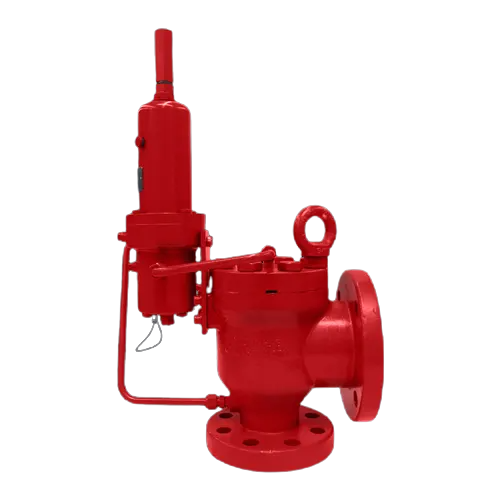

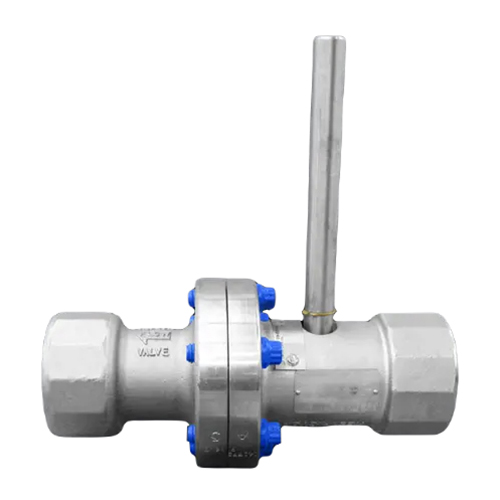

Van - các thành phần của van

Tin tức

EMERSON là Hãng nhận được nhiều sự đánh giá cao các phương diện từ phần mềm, thiết bị đo và phân tích,..do người dùng bình chọn trên tạp chí Global Control

Ngày 12/10/2022, Bảo Nghi chính thức đánh dấu cột mốc quan trọng cho sự trưởng thành của mình, cột mốc mang tên " kỉ niệm 15 năm thành lập".

Giới thiệu bơm chất lỏng model EGP của Graco 2022

CHÚNG TÔI TẬP TRUNG VÀO KẾT QUẢ

Chất lượng sản phẩm, chất lượng công trình đã được khẳng định từ khách hàng của chúng tôi.

_20240108094130.png)